![]()

Glass or panels can be positioned to the inboard (I) or outboard (O) side of the 4-1/2″ depth frame to achieve the look you require. Typical glass thickness is 1″, and can be installed from the outside or inside of the building. Special glazing pocket reducers allow the use of 1/4″ infill thicknesses, too.

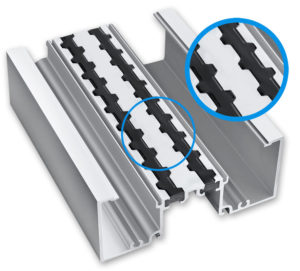

Our redesigned TU14000 I/O Series Storefront dual cavity pour and debridge thermal barriers insulate exterior surfaces from the interior to minimize temperature transfer. This provides industry accepted performance for condensation resistance and energy performance. The system is based on #12 screw fasteners which greatly decreases rework in the field.

Using the same design, assembly, and accessories as the TU14000 center glazed system allows combining inboard, outboard and center planes of glass in the same elevation with the same great performance.

Framing is compatible with Tubelite’s Medium and Wide Stile Therml=Block™ Doors.

Tubelite TU14000 I/O Series Storefront products are subjected to thorough testing by an independent laboratory, ensuring that you get the highest quality storefront framing products that the industry has to offer.

EXAMPLES >

R-Mil Warehouse

Vineyard, UT

Wilmington Gardens

Salt Lake City, UT

Baker Center

Minneapolis, MN

Glass or panels can be positioned to the inboard (I) or outboard (O) side of the 4-1/2″ depth frame to achieve the look you require. Typical glass thickness is 1″, and can be installed from the outside or inside of the building. Special glazing pocket reducers allow the use of 1/4″ infill thicknesses, too.

Our redesigned TU14000 I/O Series Storefront dual cavity pour and debridge thermal barriers insulate exterior surfaces from the interior to minimize temperature transfer. This provides industry accepted performance for condensation resistance and energy performance. The system is based on #12 screw fasteners which greatly decreases rework in the field.

Using the same design, assembly, and accessories as the TU14000 center glazed system allows combining inboard, outboard and center planes of glass in the same elevation with the same great performance.

Framing is compatible with Tubelite’s Medium and Wide Stile Therml=Block™ Doors.

Tubelite TU14000 I/O Series Storefront products are subjected to thorough testing by an independent laboratory, ensuring that you get the highest quality storefront framing products that the industry has to offer.

EXAMPLES >

R-Mil Warehouse

Vineyard, UT

Wilmington Gardens

Salt Lake City, UT

Baker Center

Minneapolis, MN

| TU14000 I/O Series Storefront Product Specifications | ||||||||

| Application: Low and mid-rise commercial buildings requiring high energy and condensation resistance performance. Description: 2” x 4-1/2” dual thermal barrier center set storefront system, screw spline or shear block connections, exterior or interior glazed. |

||||||||

| Face Width: | Overall Depths: | Glass: | Air Infiltration: | Static/Dynamic Water Infiltration: | Structural: | U-Factor:** | CRF: | Acoustic: |

| 2″ | 4-1/2″ | 1” std. (1/8″ to 1-1/8″) |

0.06 CFM/Ft.2 @ 6.24 PSF |

12 PSF – Inboard Plane 12 PSF – Outboard Plane |

30 PSF – Design 45 PSF – Overload |

U-Factor Table | 78F 72G – Outboard Plane | STC 31 OITC 25 |

**U-Factor per AAMA 1503-09: COG = 0.24

Glass Makeup: 1″ IGU – 1/4″ SNX62/27 #2, 1/2″ Argon with warm edge spacer, 1/4″ clear

| TU14000 I/O Series Storefront Product Specifications | |

| Application: | Low and mid-rise commercial buildings requiring high energy and condensation resistance performance. |

| Face Width: | 2″ |

| Overall Depths: | 4-1/2″ |

| Glass: | 1” (1/8″ to 1-1/8″) |

| Air Infiltration: | 0.06 CFM/Ft.2 @ 6.24 PSF |

| Water Infiltration: | 12 PSF – Static, 12 PSF – Dynamic |

| Structural: | 30 PSF Design, 45 PSF Overload |

| U-Factor: ** | U-Factor Table |

| CRF: | 78F 72G – Outboard Plane |

| Acoustics: | STC 31, OITC 25 |

**U-Factor per AAMA 1503-09: COG = 0.24

Glass Makeup: 1″ IGU – 1/4″ SNX62/27 #2, 1/2″ Argon with warm edge spacer, 1/4″ clear